An essential part of maintaining your garage floor that should be addressed is sealing the concrete. Even though concrete garage floors last a long time, they are porous, water, chemicals, and normal wear and tear can damage them.

Although concrete is a useful flooring option, it can become damaged, worn down, and cracked over time. Sometimes, concrete slabs become damaged and weak because they weren't built to code in the first place.

Also, the concrete might have employed materials or methods that weaken the structure, like stimulants or retarders, or they might have used too much water. Sealing your concrete floor will protect it and make it stronger, last longer, look better, and last longer, so you'll get more use out of it for longer.

You can protect the concrete on your garage floor from stains, gaps, and other damage by sealing it. This complete guide will show you how to do it.

Tips on How to Apply Garage Floor Sealers

Sealing your garage floor to look like bare concrete is easy to do yourself and can be done over a weekend. The important thing is to use the correct application methods and avoid some of the most common bad habits. So, to guide you, here are eight concrete sealer usage tips for the garage floor to ensure you get a good result.

It's important to note that these sealing tips are for people who intend to seal their garage floor and keep it the way it looks. A penetrating sealer, a densifier sealer, or a mix of the two is usually used to seal something. Visit this page to learn more about penetrating sealers.

Clear, film-forming acrylic sealants and hybrid acrylic blends are yet another popular application. These add a thin layer that makes the concrete a little darker and gives it a shiny, decorative look.

The Three Various Kinds of Sealers

Different types of sealers are used to protect concrete floors. These are topical, penetrating, and integral sealers. Because each sealer does a unique thing, we thought we'd list them all:

- Penetrating sealers: These sealants penetrate deep into the concrete and create a chemical barrier that keeps water out of the floors, extending their lifespan.

- Integral sealers: These sealants are included in the concrete mix before they leave the plant. This way, your concrete floor begins sealing once it is put down. The integral sealer works just like a topical sealer, but it starts sealing immediately, which is a big plus.

- Topical sealers: These are put on top of your flooring's concrete and protect them well. Perfect for use both inside and outside.

Application Tips for Concrete Sealant

Adhere to the Manufacturer's Instructions

You would only believe how many mistakes people make if they follow the directions. Each manufacturer has different instructions, even if you have used a sealer on your garage floor. Often, manufacturers' technical data sheets can be found online with instructions on how to use their products.

If you need clarification, call the sealer maker before you use it. Don't worry—they've heard every question before.

Take Safety Precautions

Before you start:

- Put on your safety gear.

- Wear safety gear like goggles, gloves, a respirator mask, work clothes, and thick boots.

- Since you're still working with chemicals, ensure enough air flow by opening all the doors and windows and putting up work fans.

Proper Concrete Preparation

Getting the concrete on your garage floor ready is very important if you want to use a sealer. The garage floor needs to be clean and have the right surface profile. To allow the sealer to go into the concrete or stick to the surface, most concrete floors need to have some holes in them. In most cases, if the concrete can soak up water, it can also soak up a sealer.

Ask the maker what kind of surface profile you need. After cleaning the exterior, gently sand it or use an acidic etch solution to ensure the seal works properly.

Clear and Clean the Area

You may store bikes, containers of festive decorations, cars, and other things in your garage. Clear the floor of these things. You should wait till the concrete has hardened and any stains are completely dry if you just poured it before you try to seal it.

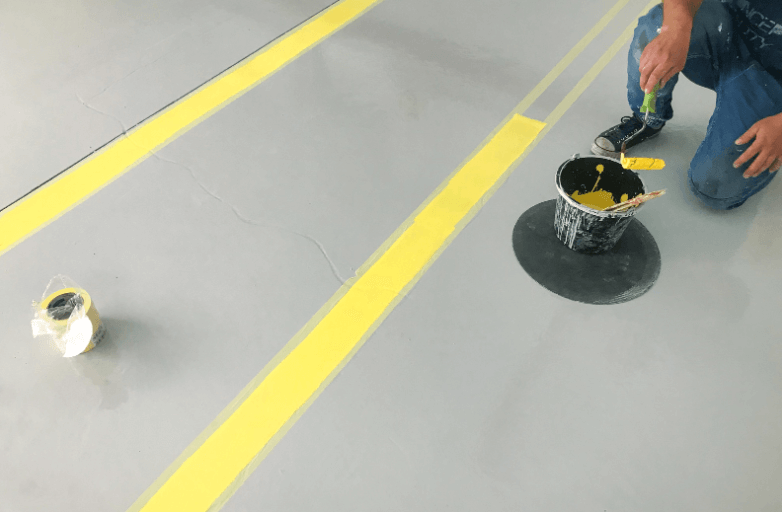

Then, it's essential to review how to clean stone floors again. Use a hose or, better yet, a pressure washer to sweep and spray your floor clean. If the hose doesn't remove the grease stains, use a concrete cleaner to focus on these spots. Be careful with this step because you'll want to ensure the floor is clean. Painter's tape over your baseboards will also keep the sealer from getting on them.

Keep a Wet Edge

When thin film-forming sealers like acrylics are used, people often complain about seeing roller signifies or lap lines. Do not let the roller's surface dry when extending the sealer. Instead, keep the edge wet at all times. Be sure to keep it damp and run it over the last pass for a few inches to make the two blend together as they dry.

Make Necessary Repairs

Before you apply the sealant to the floor, check for damage to the concrete. A concrete filler should be used to fix cracks less than 1/8 inch wide. Before applying the sealant, let the filler fully cure. Get a building specialist to check for wider holes or cracks that aren't levelled from side to side. If they find any, you may need to fix your foundation.

You could also use this time to fix any other problems in the garage, like an overhead door that won't close or a garage door opener that doesn't work. Once the sealer has dried, the new area will be ready to use.

Watch the Air Temperature Before Accessing Sealers

Acrylics and other film-forming sealers should be used when the temperature falls between 50 and 80 degrees. When it gets warmer than that, the sealant can dry too quickly, causing bubbles to form because it evaporates too quickly. Don't apply if it's going to rain in the next 24 hours or the relative humidity is above 85%.

It is usually possible to use penetrating and densifying sealants when the temperature is between 40 and 90 degrees. Always check the installation instructions with the product to ensure the temperatures are correct.

What Is the Importance of Sealing Your Concrete Floors?

Sealing your concrete floors is very important, and there are many reasons for this. We'll list some of those benefits here.

Sealant Protects Your Floors

Accidents involving oil, ultraviolet (UV) rays from the sun, and shifts in the weather can all damage concrete floors. But a good sealer can protect them. If you'd like the flooring to last much longer, sealants will help.

Sealing Extends the Life of Your Floors

As we already said, sealing the concrete floors makes them last longer than they would otherwise. It is possible to make your concrete floors last an extra 25 to 30 years if you seal them properly.

Sealed Floors are Durable

Properly sealing your floors will make them last longer. The weather won't be able to damage a sealed concrete floor, so it won't crack, scale, or have other typical concrete problems. No matter how often your floors are used, sealing them will keep them from getting damaged. Sealing your concrete floors is a great way to ensure they look great and last longer.

Maintain the Floors Colour

This year, shading concrete floors is viral. However, concrete flooring left out in the weather can quickly lose colour. So, by sealing the concrete floors, you can assist in preserving and sustaining the floor's colour, keeping them appearing clean and razor-sharp for a longer time.

Sealing Concrete Inhibits Mould

Mouldy floors are different from what people want. While it's true that adequately sealed concrete floors keep out water, mould can grow underneath them. If you properly seal your concrete floors, water won't be able to get to them. This stops mould and bacteria from growing, which keeps your floors looking better for longer.

What Kind of Finish Is Produced by Concrete Floor Sealer?

The finish on this item will dry with almost no shine. It will take more product to cover very porous concrete, and the final result will still only have a low sheen. You might see a slightly greater sheen if the concrete is hard and dense. A gloss finish will not be made with this product.

Before using any sealer, you should test it to ensure you're happy with its finish. The different types of concrete and the amount of air holes in each material affect the final finish. You should also check the floor before applying a sealer. We give you samples, so it's easy to do!

Which is best?

No matter what kind of sealant you choose for your garage floor, it will depend on the finish and result you want. The best things about a topical sealer like epoxy resin are that they make the surface:

- It is strong and not easily damaged when accidentally dropping something on it.

- It can have a flake or coloured finish for style.

- You could also fully protect an area from UV rays, which some products can do.

- Protection with a hard layer that keeps water and other liquids from getting into the concrete

- UV stable—remember that protection will depend on the product you choose.

- Long-lasting: "If you take care of the floor, the floor will take care of you," and several projects done 8–10 years ago have proven this.

- It is simple to take care of and clean, mainly with a sweep and cleaning products that work like detergents. An auto scrubber might be a better choice for areas with a higher risk of slipping and commercial projects.

To choose the best sealant for your garage floor, talk to someone who understands what you want to do. Garage floors should be beneficial, easy to clean, and built to last. You'll get this if you seal your garage floor with a suitable epoxy resin coating.

Conclusion

Sealing a concrete garage floor is essential to keeping it looking good and lasting long. Water, chemicals, and regular wear and tear can damage concrete floors. Sealing your concrete floor keeps it from getting spots, gaps, and other damage.

Penetrating sealers, integral sealers, and topical sealers are the three types of sealers used to prevent water from getting into concrete floors. Penetrating sealers put a chemical wall around the floors that keeps water out, making the floors last longer. Integral sealers start protecting the concrete mix as soon as it leaves the plant, and external sealers are put on top of the floor to keep it safe inside and out.

To use a concrete sealer, follow the manufacturer's directions, stay safe, and make sure the floor is ready. Remove bikes, decorations, and cars from the area and clean it up. Then, wait until the concrete is complex and the stains are fully dry. Use a hose or pressure washer to sweep and spray the floor. For grease spots, use a concrete cleaner. You can also keep sealers from crossing borders by putting painter's tape over them.

To avoid roller marks or lap lines, keep the edge wet using thin film-forming sealers like acrylics. This will help the two sealers stick together while they dry.

Before you put sealant on your garage floor, ensure there is no damage to the concrete and give it time to cure fully. Talk to a building expert if you need to fix holes or cracks that are bigger or not level from side to side. Sealing your concrete floors is essential for many reasons, such as keeping oil, UV rays, and changes in the weather away from them, making them last longer, keeping the colour, and stopping mould growth.

Use acrylics and film-forming sealers when the air temperature is between 50 and 80 degrees. Penetrating and densifying sealants would be helpful when the air temperature is between 40 and 90 degrees. Before you apply the sealer, make sure that the product is compatible with the temperature range and that the installation instructions are correct.

When concrete floor sealer dries, the finish will have almost no shine, resulting in a low sheen. Test any sealer to ensure you like how it looks before you use it.

The finish and result you want will help you choose the best sealer for your garage floor. Concrete is easy to clean and maintain, and topical sealers like epoxy resin give the concrete a strong, non-damaging surface with a flake or coloured finish. They also protect the concrete from UV rays and form a hard layer that keeps water and other liquids from getting into it. Auto scrubbers might be better for business projects and places where people are more likely to slip.

Picking the proper sealant for your garage floor is essential for how well it works, how easy it is to clean, and how long it lasts.

Content Summary

- Sealing your garage floor's concrete is crucial for its longevity.

- Despite concrete's durability, it's porous and vulnerable to damage.

- Incorrectly built concrete slabs can weaken over time.

- Sealing enhances concrete floor strength and appearance.

- Seal your garage floor to protect against stains and cracks.

- Learn how to seal your garage floor effectively.

- Proper application ensures lasting results with concrete sealers.

- For a bare concrete look, choose the correct sealing method.

- Penetrating sealers delve deep to protect from water damage.

- Integral sealers start protecting as soon as the concrete is laid.

- Topical sealers provide external protection for interior and exterior use.

- Always adhere to the manufacturer's sealing instructions.

- Safety is paramount; wear gloves, goggles, and respirator masks.

- Properly preparing the concrete surface is essential.

- Ensure the concrete is porous enough to absorb the sealer.

- Clear your garage floor of all items before sealing.

- Clean the concrete floor meticulously, focusing on grease stains.

- To prevent roller marks, always keep a wet edge during application.

- Address any concrete damage before applying sealant.

- Mind the air temperature when sealing for optimal results.

- Sealants guard your floors against oil spills and UV rays.

- Properly sealed floors can last an additional 25-30 years.

- Sealed floors resist typical concrete issues like cracking.

- Preserve your concrete floor's colour with sealing.

- Sealed floors prevent mould growth by blocking moisture.

- The finish of a concrete sealer is usually a low sheen.

- Always test the sealer's finish on a small patch first.

- The ideal sealer varies based on your desired finish.

- Topical sealers like epoxy resin create a sturdy surface.

- Choose UV-stable sealers for protection from sun rays.

- Properly maintained epoxy-coated floors last 8-10 years.

- Cleaning sealed floors is easy with just sweeping and detergent.

- Seek expert advice for choosing the perfect garage floor sealer.

- Epoxy resin coatings provide both style and protection.

- Sealing prevents chemical damage and everyday wear and tear.

- Improper construction methods can compromise concrete's strength.

- Sealed floors offer enhanced longevity and better aesthetics.

- To maintain the natural look, opt for a penetrating sealer.

- Penetrating sealers create a moisture-resistant chemical barrier.

- Sealers integrated within concrete offer immediate protection.

- Proper application ensures optimal performance of topical sealers.

- Follow the manufacturer's guidelines to maximise sealant efficiency.

- Safety precautions ensure a risk-free sealing process.

- A thoroughly prepped concrete surface ensures sealer adherence.

- A clean floor is crucial for effective sealing.

- Constantly maintaining a wet edge avoids unsightly lap marks.

- Address concrete flaws for an even, seamless seal.

- Weather conditions can affect the sealant's drying process.

- Sealed concrete floors are resistant to UV, oil, and weather damage.

- Epoxy resin coatings offer the perfect balance of aesthetics and protection.

Frequently Asked Questions

Resolving every two to three years is recommended, but this will depend on the type of sealer used and how often it was used.

You can seal your garage floor yourself, but hiring a professional will ensure the job is done correctly.

Before sealing, fill any cracks with concrete filler and ensure the surface is as smooth as possible.

Before driving on the sealer, it is best to wait until it has completely cured, which could take one to several days.

Yes, cleaning the surface thoroughly is necessary to ensure the sealer will adhere correctly.